2024

2024

Atria celebrated the opening of its new poultry unit

Atria celebrated the opening of its new poultry unit in Nurmo in August. One of the guest speakers and a ribbon-cutter at the event was Sari Essayah, Finland's Minister of Agriculture and Forestry. In addition to the speeches, the opening ceremony included delicious food and a tour of the new factory and the Nurmo area.

2024

2024

Atria acquired Gooh!

Atria acquired the convenience food business Gooh! from Lantmännen Cerealia. Atria owns the entire share capital of the newly formed company Atria Gooh AB. All 65 employees will join Atria in the transition. "For us, this is a strategic and long-term acquisition to grow in the convenience food category", says Jarmo Lindholm, EVP, Atria Sweden.

2024

2024

Atria bought the entire share capital of Well Beef Ltd

Atria bought the entire share capital of Well Beef Ltd and owns 100 percent of Well Beef's shares through the share transaction made on April 2, 2024. In 2016, Atria bought 70 percent of Well Beef's shares, and in 2021, 20 percent. Well Beef has a strong market position in Finland as a manufacturer of high-quality hamburger patties and kebab products. Well Beef's product selection complements well Atria's selections in beef products.

2023

2023

Kai Gyllström was appointed CEO of Atria Plc as of June 1, 2023

Juha Gröhn, Atria's long-time CEO, retired on 31 May 2023. The Board of Directors of Atria Plc appointed M.Sc. (Econ.), MBA Kai Gyllström as the new CEO of Atria Group as of June 1, 2023.

2022

2022

Atria — 120 years of respect for the planet, people and the food we eat

In 2023, Atria celebrates its food journey that began 120 years ago in Finnish family farms and whose recipe will last for generations to come: Good food — better mood.

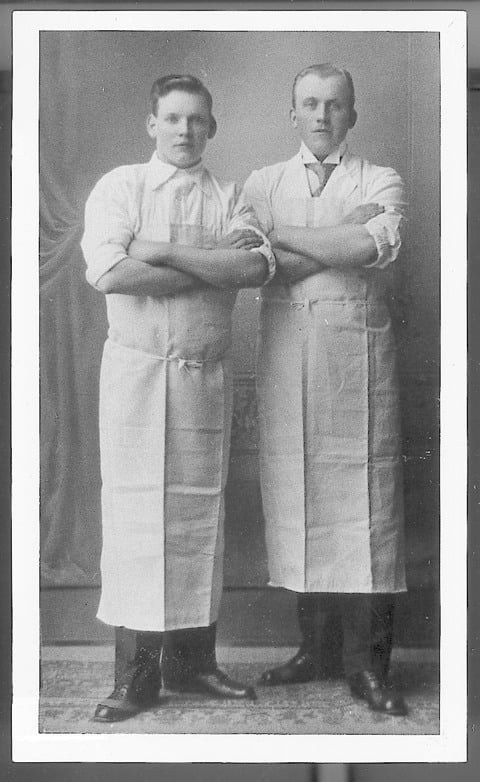

Atria's food journey begins when a small group of farmers set up the first Finnish cooperative meat company in 1903. Initially it focuses on selling and brokering livestock, but within a few years the cooperative also starts trading and processing meat. The first meat products sold are delicious sausages, which are well received by the consumers.

From those strong agricultural roots, Atria has grown over 120 years into a successful Finnish and Northern European food company. We make good food in Finland, Sweden, Denmark and Estonia. Our products and brands are well known and desired. In Finland, the Atria brand is one of the best-known Finnish food brands. Lithells, founded in Sweden in 1907, is the oldest Swedish brand. Lönneberga and Sibylla brands have also seen several generations and today Sibylla is Atria's most international brand. In Denmark our well-known brands are 3-Stjernet and Aalbaeck Specialiteter, and in Estonia Maks & Moorits.

In total, there are already around 4 400 Atria people in four different countries. We are united by our passion for good food at every meal - we are involved in people's everyday lives and celebrations, in the moments of our lives. This is what we want to continue to do in the future. That's why we act with respect for the planet, product and people.

2021

2021

Atria invests EUR 30 million in restructuring of the Swedish production

Atria invests EUR 30 million to restructure the Swedish production. The investment includes an expansion and new machinery in the plant in Sköllersta. With the restructuring, the production in Malmö will be moved to the plants in Sköllersta and Moheda in Sweden and to Hansted in Denmark. The move is expected to be completed during 2023.

By centralizing production to fewer plants, Atria wants to ensure its future competitiveness with more efficient production and logistics with a lower climate footprint.

– This investment enables long-term sustainable operations for Atria in Sweden, where we can meet the demand of our consumers also in the future, says Jarmo Lindholm, Executive Vice President, Atria Sweden.

Atria has approximately 160 employees in Malmö. The move can be completed in 2023 at the earliest and until then production will continue in Malmö. After that, Atria plans to sell the factory building in Malmö.

2021

2021

Divestment of Atria's Russian subsidiary OOO Pit-Product

Atria entered into an agreement to sell its Russian subsidiary OOO Pit-Product to Limited Liability Company Agricultural Complex Mikhailovskiy, member of the Cherkizovo Group. The divestment of OOO Pit-Product to the buyer was completed in April 2021. The sales agreement does not include Atria Russia's other subsidiary Sibylla Rus LLC, which conducts fast food business in Russia.

The sales price is approximately EUR 30 million. Atria acquired Pit-Product in 2005.

2020

2020

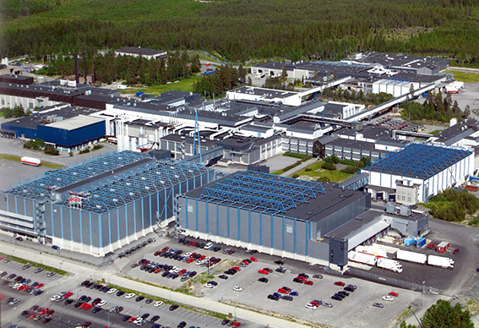

Atria makes the largest investment in its history – €155 million to expand poultry production

Atria has made a decision to invest in expanding its poultry production capacity. The company is investing approximately €155 million to construct a new processing plant on its existing site in Nurmo. The investment includes new slaughtering, cutting and packaging lines. This investment will increase poultry production capacity by approximately 40%.

The new processing plant will help the company to meet growing consumer demand, and it will strengthen Atria's position as market leader for poultry products in Finland. The new plant and increased capacity will enable Atria to increase its exports of poultry products. The investment will enable the development of a product portfolio for further processed products.

"The planning phase of the construction project and the application processes for the necessary official permits began about a year ago. The poultry production facilities in Nurmo need to be modernized, and we need to increase our capacity to be able to better meet future consumer demand. In order to strengthen our position as the number one poultry producer in Finland, we decided to make the largest single investment in our company's history," explains Atria's CEO Juha Gröhn.

The new processing plant will help the company to meet growing consumer demand, and it will strengthen Atria's position as market leader for poultry products. Construction work at the site of the new plant will begin as soon as possible with an estimated completion date of 2024 at the earliest.

2020

2020

Atria Finland renews its traditional brand logo

Atria, which turns 117 this year, is renewing its brand logo in Finland. The reform will come in packaging from August 2020. At the same time, Atria brand image of packaging is being renewed: traceability, responsibility and Finnish origin are more clearly emphasized in product packages.

- According to researches, Atria's traditional red-green brand logo is one of Finland's best-known food industry logos. In its current form, the logo has served us since 1991. As the world and brands change, there is a need to modernize our logo in line with the brand's values, says Sanna Päällysaho, Atria Finland's Marketing Director.

The new logo communicates more clearly the values of the Atria brand: long traditions and strong know-how, Finnish family farms behind the raw material of the brand's products, and responsibility. The renewal of the logo and packaging visuals will continue to renew Atria's brand image. Our aim is to bring out approachability, community and warmth.

- The reform work was started already last year. This has been a big effort for Atria Finland's marketing team. It has involved a lot of design and multi-stage studies. One of the efforts is to make the logo visible on packaging and numerous other surfaces. The logo was created in cooperation with the British design agency BrandMe, says Päällysaho.

2018

2018

Atria Solar Power Park completed

The last panels of the Atria Solar Power Park were installed in September 2018 and the project is fully ready for solar panels. Atria Nurmo's factory has the largest solar park in Finland. The construction project completed in its timetable was launched in June 2017 and has produced energy for Atria's needs since July 2017.

Concerns about climate change have brought a variety of clean energy options to the food industry too. One of the alternatives is solar energy. Atria wanted to seize a clean and domestic alternative and built the largest industrial solar solar power park in Finland.

At the same time, the Atria's solar project promotes technological development as the project identifies information for general knowledge. The energy technology findings of the Solar Power Park will benefit not only Atria but also future solutions in the field. The project will continue in the next phase for studies on electricity storage and electricity control.

Facts and figures about Atria's Solar Power Park:

- The total investment of the solar power station is EUR 6.8 million. The work has been carried out jointly with Solarigo Systems Oy. Atria Solar is part of energy project projects, which have been granted state subsidies of 2.72 million.

- The solar power station's peak power is about 6 MWp and it generates 5 percent of the yearly electricity demand of the Nurmo factory, ie about 5,600 MW. This amount would be enough to accommodate 3,000 apartment buildings for electricity consumption. At its best, Atria's solar power park produces about 50 megawatt hours per day.

- All solar energy is used for the Nurmo factories, including at weekends.

- The solar park has about 22,000 individual solar panels. The size class corresponds to nine football fields. Atria's solar park produces 10 % of all solar energy produced in Finland.

2016

2016

Atria is expanding onto the growing Swedish chicken market

Atria is expanding its operations onto the growing Swedish chicken market by buying Lagerbergs, one of the country's leading poultry companies.

In Sweden, the popularity of Swedish-produced chicken is increasing steadily by more than five per cent annually. This acquisition will enable Atria to keep pace with this growth thanks to the well known and highly respected Familjen Lagerbergs brand, which belongs to Lagerberg i Norjeby, a company that has been operating in Southern Sweden for more than 50 years. The company controls the entire poultry chain: chicken rearing, slaughtering, butchering and processing, as well as sales to stores and professional kitchens. In addition to the chickens produced at its own rearing facilities, Lagerbergs has several contract producers located near its production plants.

In June – only a few months after the acquisition – Atria announced its intention to make significant investments in developing its chicken production in Sweden. Over a three-year period, Atria will invest EUR 14 million in developing and expanding its operations. The major modernisation programme will stretch from farms and rearing facilities to industrial production and onwards to consumers in the form of delicious Lagerbergs chicken products.

2015

2015

World-class pig cutting plant to be completed in Nurmo

Atria continues to invest in Finnish meat production: the pig cutting plant in Nurmo will be one of the world’s leading cutting plants by 2017.

Atria will build nearly 4,500 square metres of new production facilities next to the existing facilities. The high-tech cutting plant will improve the quality and efficiency of production, along with product and occupational safety. The old facilities will also be renovated and automated. Atria will invest around EUR 36 million in the new cutting plant.

2015

2015

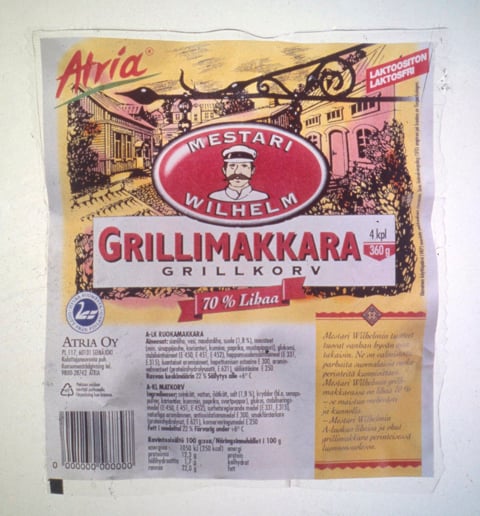

Finns are enthusiastic barbecuers

More than 90 per cent of Finns barbecue at least in the summer, and one in ten even does it in the winter, shows an extensive barbecue survey conducted by Atria in the spring.

Most Finns associate barbecuing with summer holidays and sunshine. One in three of those who participated in Atria’s survey will only barbecue in fair weather. More than half of Finns use gas barbecues, on which they most often cook various sausages. These are savoured by 77 per cent of barbecuers. The second most popular food to barbecue is vegetables. Sausages and vegetables are followed by whole-meat products, pork and chicken. The most important qualities of barbecue foods are freshness, taste and origin. Around 75 per cent of households buy Atria’s barbecue products.

2015

2015

Atria acquired organic cold cuts manufacturing Aalbaek Specialiteter in Denmark

Atria acquired the uppers of Danish bread manufacturing Aalbaek Specialiteter A / S business. Aalbaek is Denmark's largest organic cold cuts manufacturer. Aalbaek Specialiteter was founded in 1920 and is one of the largest European manufacturers of high-quality organic meat products. Aalbaek's product range includes a variety of premium cold cuts, liver pâté and bacon.

2014

2014

Atria acquires Saarioinen’s meat operations

Atria’s position as a front runner in the Finnish meat industry strengthens when it acquires Saarioinen’s procurement, slaughtering and cutting operations for beef, pork and chicken.

Finnish consumers value a transparent production chain and information on the origin of meat. Atria was the first Finnish meat industry company to introduce farm-level traceability for beef, pork and chicken. The acquisition in 2014 of Saarioinen’s procurement, slaughtering and cutting operations for beef, pork and chicken consolidates the position of Finnish meat in the food market and adds even more variety to Atria’s selection.

As part of the deal, Saarioinen’s chicken production in Sahalahti (Kangasala) and slaughterhouse in Jyväskylä are transferred to Atria. Atria and Saarioinen also sign an agreement for meat deliveries for Saarioinen’s production of convenience foods and other products.

The transaction strengthens Atria’s position particularly in chicken products. The popularity of chicken among Finns began to grow in the mid-1990s and has increased significantly in the 2010s.

2013

2013

Russian operations centralised in St Petersburg

Atria discontinues primary production in Russia and centralises its operations in St Petersburg, in the efficient Gorelovo plant.

After many years in the red, Atria Russia shifts up a gear in business development.

Atria discontinues primary production of pork at Moscow-based Campofarm and shuts down a Campomos plant, also in Moscow. Pizza production is transferred to a plant in Gorelovo, St Petersburg. Campomos’s production of meat products has already been centralised in Gorelovo before. Sales in Moscow continue under the CampoMos brand.

2013

2013

Lithells sausages – 100% flavour!

Atria Scandinavia invests heavily in the Lithells brand. The ‘Oskar Lithells finaste’ and ‘Lithells Världskorv’ concepts launched by the company are well received and increase the Lithells brand’s popularity in Sweden.

2013

2013

A new Atria Way of Work

Atria Group’s employees define the Group’s shared practices and values – the Atria Way of Work.

The Atria Way of Work (WoW) principles are defined in 2013 as an expression of the employees’ team spirit and shared intent. WoW discussions conducted in various countries of operation are a real success: some 75 per cent of Atria employees in Finland, Sweden, Denmark and Estonia want to have their say on the subject. At Atria Russia, value discussions have already been held earlier.

WoW agents lead discussions on topics such as what is the most important operating principle for personnel in each country.

-

- Atria Way of Work:

- We focus on consumers and customers

- We are hungry for success

- We deliver quality

- We enjoy our work

- Atria Way of Work:

2013

2013

Feed production capacity almost doubles

A new poultry feed plant is completed in Koskenkorva. As a result, A-Rehu’s production capacity almost doubles.

The new poultry feed plant in Koskenkorva is constructed at a site that already houses A-Rehu’s facilities for pig and cattle feed production. The new plant can produce up to 100 million kilograms of poultry feed a year. A-Rehu’s pig, cattle and poultry feed capacity in Koskenkorva rises to 240 million kilograms a year.

The poultry feed plant, which is the result of cooperation between producers and A-Rehu, ensures that Finland will continue to have domestically-owned feed production in the future as well. A-Rehu is a company owned by Atria and Finnish livestock farmers.

2013

2013

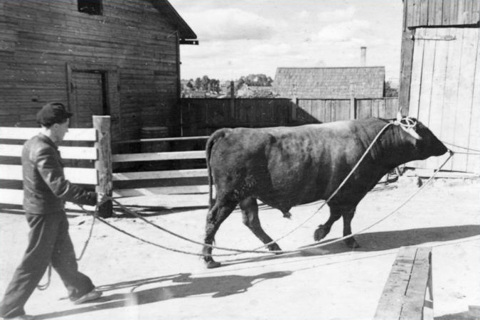

New cattle slaughterhouse opened in Kauhajoki

Atria’s new slaughterhouse in Kauhajoki is the most modern in Europe.

Atria centralises its cattle slaughtering and cutting operations in Kauhajoki. The facility combines the latest technology with Atria’s long experience in cattle slaughter.

Atria slaughters about a half of all cattle slaughtered in Finland.

The average slaughter weight of cattle is on the rise. The new technology enables Atria to hygienically process bigger animals than before. Along with efficiency, attention has been paid to animal welfare, hygienic working methods and safety at work.

2012

2012

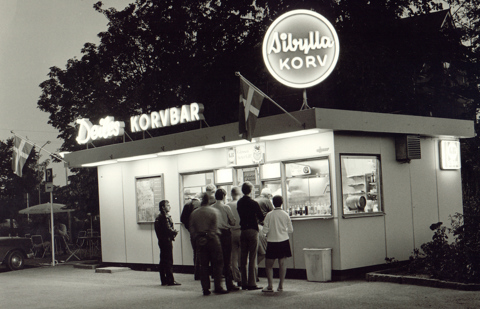

Sibylla on sale in more than 3,300 outlets

Sibylla products are an international success story: they are already sold in more than 3,300 outlets in countries around the Baltic Sea.

Sibylla joined the family of Atria brands in the late 1990s and is one of Sweden’s best-known brands. The first Sibylla hot dogs were brought to the market in Sweden in 1932.

In 2012, Sibylla products are enjoyed by people in Sweden, Finland, the Baltic countries, Russia and Poland – in more than 3,300 outlets. About a third of these are located in Sweden. Sibylla products are most often sold at petrol stations. In Sweden, Sibylla also has its own street kiosks.

The selection includes hamburgers, hot dogs, sausages, chips, meatballs, meat-filled pastries and kebabs, depending on the country and customer. Sibylla belongs to the Nordic Fast Food (NFF) chain, in which the majority shareholder is Atria Concept, an Atria Scandinavia subsidiary. Other owners are franchise entrepreneurs of the chain.

2012

2012

10th anniversary of 100 Young Chefs

The Atria 100 Young Chefs training programme celebrates its 10th anniversary. Over the years, the course has been attended by some 800 young people who love food – among them some of today’s top chefs.

The Atria 100 Young Chefs course is more than just cooking. It is a learning and training environment in which the participants also practise drawing up a successful business plan, learn about product development and discover their strengths.

Attendance is not limited to top chefs, although many young people who enter the programme have already gained some valuable experience. The course is immensely popular year after year, and not least because of distinguished lecturers. In the anniversary year, the programme was led by Aki Wahlman.

The Finnish Gastronomic Society has awarded the Atria 100 Young Chefs programme a commendation for its efforts to promote Finnish food culture.

2012

2012

Atria acquires Best-In pet foods

Atria acquires the entire stock of pet food manufacturer Best-In.

Best-In, a company focusing on dog and cat food, is transferred to Atria’s ownership when it purchases HK Ruokatalo’s share in the company.

In its first years of operation, the best-known product of the company, founded in 1970 in Kuopio by co-operative slaughterhouse Lihakunta, was Mustin Murkina sausage for dogs. The first Best-In-branded sausages were fed to dogs in the late 1970s. Another successful brand of the company is Hubert, a range of fresh pet foods and titbits.

2011

2011

Maks & Moorits brand is revamped

Atria Baltic revamps its best-known brand, Maks & Moorits, to respond to consumer wishes.

Additives are a sensitive subject in Estonia, especially monosodium glutamate (E621). The new Maks & Moorits range is free of monosodium glutamate, a pioneering move in the Estonian meat product market. The new products are packed in modern, user-friendly packaging that ensures a long shelf life. Maks & Moorits’s roots go back to the 1910s.

2011

2011

A new home for Lönneberga products

Atria Scandinavia is making a concentrated effort to develop its operations and, among other measures, transfers the production of the valued Lönneberga products from Halmstad to the Malmö plant.

The greatest challenge in moving the production of meat products from one factory to another is ensuring the continuity of production and the quality of the products. Especially with a product family such as Lönneberga. Its roots go back to the 1930s, and it is one of Atria’s strongest brands in Sweden. All Lönneberga-branded products are of premium quality, and they are made from Swedish raw materials.

Atria Scandinavia’s plant in Fosie, Malmö was built in 1977 and has about 200 employees. The plant is Atria’s second largest in Sweden, after Sköllersta. The Lönneberga brand was transferred to Atria in 2007 when it acquired Sardus.

2011

2011

Juha Gröhn elected as Atria CEO

Juha Gröhn, a man known to the company’s employees and producers as well as the meat industry and the entire food sector, takes the helm at Atria.

Juha Gröhn, MSc (Food Sc.) (b. 1963), has had a long career at Atria: before the managing directorship of Atria Group, he was in charge of Atria Scandinavia’s operations. He has also worked in various managerial positions at Atria Finland and Atria Baltic. He has been a member of Atria’s management team since 1993. Gröhn was actively involved when the company implemented an extensive change and adjustment programme in 1991–1996.

“Juha Gröhn has solid experience in the meat sector. He started his career at Lihapolar Oy in 1990 and has worked at Atria Plc since then. He is familiar with the meat sector and knows the challenges of primary production and industry. Throughout his career, he has worked in close cooperation with businesses in the consumer goods retail trade in Finland, Estonia and Sweden. Juha is known for his open and straightforward management style, and I am convinced that under his leadership, Atria will have everything it needs to succeed in the highly competitive food industry,” says Martti Selin, chairman of Atria Plc’s Board of Directors

2011

2011

Bravuuri and Kulinaari arrive on the consumer’s table

Over the course of a couple of years, Atria launches two new product families: Atria Bravuuri and Atria Kulinaari. All meat used in the products comes from Finnish farms.

After thorough consumer research and product development, Atria brings to the market two new product families: Atria Bravuuri and Atria Kulinaari.

The Atria Bravuuri products are designed to meet consumers’ changed cooking needs. Bravuuri offers all the necessary ingredients in a single package for a quick, easy meal.

The Atria Kulinaari product family consists of premium cold cuts. The products are made from 100% Finnish meat, and their meat content is high.

2011

2011

Farm of origin put on chicken packaging

Labels are attached to Atria Finland’s fillet product packaging displaying the name of the family farm that produced the meat.

Consumers want to know where their food comes from. Knowledge of the origin increases consumers’ trust. Atria introduces farm of origin labelling in chicken products. Consumers can access information online regarding the farm, quality control and animal welfare.

All of Atria’s chicken producers embrace Atria Family Farm labelling.

“Chicken farming provides a livelihood for normal Finnish families. Every chicken comes from someone’s farm. We also hope to show Atria’s domestic production in a positive light,” says Mari Penttilä, farmer’s wife at Larvatalo farm.

- One in five Finnish consumers are concerned about the ethics of meat production and animals’ rearing conditions.

- 70% of Finns wish to receive more information on the origin of meat before making a decision to buy.

- More than 60% wish to receive more information on production conditions and are interested in animal welfare.

Sources: MTT Agrifood Research Finland, National Consumer Research Centre. 2010. RISC attitude survey 2011.

2011

2011

Major investments in workplace well-being

Atria’s Early Caring programme is among the most extensive workplace well-being projects in Finnish industry. The results are excellent.

Atria’s Early Caring programme, which has been running for three years, applies to all of the company’s 2,400 employees. It has increased the working capacity and well-being at work of the personnel as a whole, reduced absences due to sickness and accidents, and prevented early retirement. Early Caring is a new attitude adopted by the company.

“The project has yielded exceptionally good results in reducing sickness absences. Work in the meat processing industry is repetitive and physically straining,” says Atria Finland’s leading occupational health physician Timo Kinnunen.

A new occupational health centre was opened at Atria’s Nurmo site as part of the programme, and it proved to be useful for promoting workplace well-being. The building provides modern premises for ten occupational health professionals.

2010

2010

Estonian operations centralised in two plants

In order to improve its productivity and competitiveness, Atria Baltic concentrates its Estonian operations in two plants instead of three: Valga and Vastse-Kuuste in Southern Estonia. Atria also owns large piggeries in Estonia.

2010

2010

CampoMos products are popular in Moscow

Atria Russia invests heavily in revamping its CampoMos brand, particularly in Moscow.

Moscow is by far the largest market for the food industry in Russia. The buying power of its 11 million consumers is nearly double that of the rest of Russia. Atria’s main brand in Moscow is CampoMos.

2009

2009

New plant completed in St Petersburg

Atria Russia opens the most modern food factory in the country, doubling Atria’s production capacity in the St Petersburg region.

Atria Russia’s major investment in the modernisation of production and logistics is completed in the Gorelovo industrial estate, some 20 kilometres from the centre of St Petersburg, in 2009. The plant, which uses the latest Western process technology, and the adjacent logistics centre double Atria’s capacity to produce Pit-Product meat products.

2009

2009

First corporate responsibility report released

Atria deepens its corporate responsibility dialogue with stakeholders and publishes its first report on the subject.

Operating responsibly and discussing operations openly has become a key challenge for the food industry. As Finland’s largest meat processing company and a leading food industry group in the Nordic countries, Russia and Estonia, Atria engages in increasingly active dialogue with its stakeholders on matters of responsibility. As part of this dialogue, Atria publishes its first Corporate Responsibility Report in 2009.

“Atria strives to lead the way in responsible food production in all countries of operation. It is important to us to continue reducing our environmental impact and to promote the welfare of production animals. Further areas of emphasis are the promotion of product safety and the healthiness and nutritional value of our products. Other priorities include ensuring the well-being and competence of our employees and increasing open dialogue with various stakeholder groups,” says Merja Leino, director in charge of the development of Atria Group’s corporate responsibility, product safety and quality.

2008

2008

Foothold strengthened in Estonia

Atria strengthens its position in Estonia and the other Baltic countries by acquiring two Estonian meat processing companies, Wõro Kommerts and Vastse-Kuuste Lihatööstus.

Atria acquires two Estonian companies in 2008, making it the country’s second largest meat company.

Wõro Kommerts has special expertise in meat products. It is Estonia’s second largest manufacturer of these products. Other products in its portfolio include smoked sausages as well as cooked and barbecue sausages.

Vastse-Kuuste Lihatööstus is known for its cold cuts. Also valued are its sausages and consumer-packed meat.

The production plants of both these companies are located close to the city of Tartu.

2008

2008

Atria enters the Moscow market

Atria acquires meat processing company Campomos, which mainly operates in Moscow, doubling its operations in Russia.

Atria acquires meat processing company Campomos, which mainly operates in Moscow, in 2008. Campomos’s main products are sausages and pizzas. The company’s brand is CampoMos and main market the metropolis of Moscow. Half of the company’s products are sold there and about a fourth in St Petersburg.

Campomos employs some 1,000 people, and its production is centralised in Moscow. The company is also involved in primary production: it owns farmland and a large piggery. Established in 1989, Campomos is the first Western meat industry company in Russia.

2008

2008

Atria acquires innovative Ridderheims

Ridderheims Delikatesser, which specialises in premium delicatessen products, joins the Atria family of companies.

The selection of fresh delicatessen products offered by Ridderheims is the broadest in the Nordic countries. It includes beer sausages, premium cheese and hams, and marinated products, such as sun-dried tomatoes, olives and garlic. The company, founded by Christer Ridderheim, is known in the food industry for its high level of innovation.

2007

2007

Baltic operations centralised in Estonia

Atria shuts down its plant in Lithuania and concentrates its production in the Valga plant in Estonia.

2007

2007

Strong presence established in Scandinavia

Atria acquires Sardus, a Swedish producer of cold cuts and convenience foods. The deal brings Atria 14 new brands, 13 new production plants and about a thousand new employees.

Sardus, the new Atria subsidiary, is one of Sweden’s leading manufacturers of cold cuts and convenience foods, and a major supplier of frozen products to catering businesses. Sardus has many successful brands: Arboga Pastej, 3-Stjernet, Pastejköket and Lönneberga. Atria’s selection also expands to cheese. Falbygdens Ost in one of Sweden’s largest cheese producers.

Following the acquisition of Sardus, Atria establishes a new business area, Atria Scandinavia, in Sweden and Denmark in 2007. The deal is part of Atria’s long-term plan to constantly strengthen and develop Atria as a Nordic meat and food company. The plan encompasses the acquisition of Lithells, Samfood and Sardus.

2007

2007

Atria acquires Liha-Pouttu

Atria acquires Liha-Pouttu Oy’s meat procurement, slaughtering and meat cutting operations. Meat procurement volumes grow from 140 million kilograms to 155 million kilograms.

2006

2006

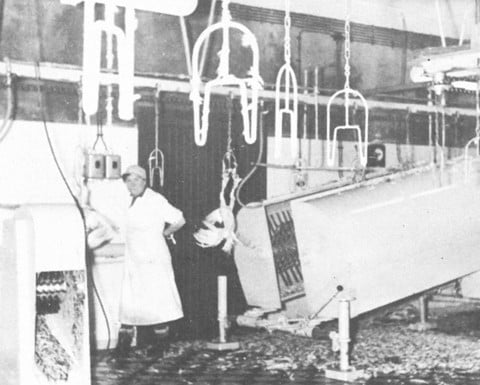

Europe’s most modern slaughter line completed in Nurmo

A pig slaughterhouse equipped with cutting-edge technology is opened at the Nurmo plant. It secures Atria’s competitiveness in the EU pork market.

A pig slaughterhouse that doubles the pig processing volume is opened at the Nurmo food factory. The production facilities are almost tripled.

The facilities are equipped with the latest technology, and the production line uses robotic automation. Attention is also paid to animal welfare and personnel’s working conditions.

The slaughterhouse, which costs more than 20 million euros, fulfils a major need: Nurmo already processes 35 per cent of Finland’s pigs.

2006

2006

Atria acquires A-Farmers

Atria Group acquires nearly the entire share capital of A-Farmers. The deal streamlines meat procurement and strengthens Atria’s entire production chain. Atria-branded products are 100% domestic meat, and Atria purchases its pork, beef and poultry from A-Farmers.

2006

2006

Seppo Paatelainen retires

CEO Seppo Paatelainen, who has been at the helm of Atria for two decades, retires. Matti Tikkakoski is elected as his successor.

2005

2005

Industry and primary production in Estonia

Atria expands to Estonia by acquiring Valga Lihatööstus, a company that also owns piggeries.

Valga Lihatööstus, the company acquired by Atria, controls the entire meat chain. It owns Estonia’s second largest piggery as well as a slaughterhouse, meat cutting department and meat product plant in Valga. The company has customers in all of Estonia’s key retail chains.

The Valga-based company’s products are also sold in Latvia and Lithuania, where Atria has its own production . In the deal, Atria obtains one of Estonia’s oldest and most valued meat product brands, Maks & Moorits.

2005

2005

Atria expands to Russia via St Petersburg

Atria takes a major step into the Russian market by acquiring St Petersburg-based meat processing company Pit-Product.

Pit-Product, acquired by Atria in 2005, has grown quickly in the St Petersburg market, which has a population of nearly five million people. In just a few years, it has become the area’s largest producer of processed meat products. The company’s market share is about 20 per cent. Its main products are different types of sausages.

In the mid-2000s, retail trade in St Petersburg is undergoing major change. Although traditional marketplaces and market halls continue to dominate, the western model of retail chains is quickly gaining ground.

Pit-Product has two plants in St Petersburg. Atria estimates that their capacity will not be enough for the growing St Petersburg market and begins to immediately plan a new factory in Gorelovo.

2004

2004

First-class fodder company founded

Atria and the co-operatives Itikka and Lihakunta establish a new, nationally strong fodder company, A-Rehu.

A-Rehu, established in 2004 by Atria and the co-operatives Itikka and Lihakunta, markets cattle and pig fodder nationwide. Existing skills and knowledge of fodder marketing and feeding consultation are brought under the same roof. The goal is to secure the future competitiveness of Finnish meat and milk production.

The company’s importance increases considerably after about ten years, when a new poultry feed plant is built in Koskenkorva.

2003

2003

Expansion to the Baltic countries begins in Lithuania

Atria acquires its first company in the Baltic region. Meat processor Vilniaus Mesa, based in Vilnius, Lithuania, is merged into the Group.

Vilniaus Mesa, acquired by Atria in 2003, is a meat processor with long traditions and an established position on Lithuanian tables. The company mainly manufactures sausages, and also exports them to other countries in the Baltic region. At the time of the acquisition, the company is developing rapidly – the following year, a new, modern meat product plant is completed in Vilnius.

2003

2003

The first 100 years – Atria celebrates

Atria’s 100th anniversary gives rise to themes of the future, even institutions: Atria’s Future Seminars, Finnish Barbecuing Championships and the Atria 100 Young Chefs training programme.

2002

2002

Atria grows in Sweden

Atria acquires the operations of Swedish Samfood and becomes the largest producer of retail products in the industry.

In 2002, Atria acquires the operations of Samfood, employing some 600 people, from the Federation of Swedish Farmers (LRF). The company is merged into Atria Lithells. It becomes a major producer of retail products in Sweden. Lithells supplies meat products, such as sausages, consumer-packed meat and convenience foods, to retailers and the catering sector.

The deal also includes fast food operations, but in this area the number one brand is still Sibylla, acquired as part of Lithells. Purchasing Samfood contributes to Atria’s growth in the Nordic countries and internationally.

2001

2001

Meat procurement concentrated in one company

Atria and the co-operatives Itikka, Lihakunta and Pohjanmaan Liha establish a joint company for meat procurement, A-Farmers Ltd. It becomes Finland’s leading meat supplier.

In the early 2000s, annual meat production in Finland totals about 340 million kilograms. More than a third of this is purchased by A-Farmers Ltd, a new company founded by Atria, Itikka, Lihakunta and Pohjanmaan Liha in 2001. The company becomes the country’s leading meat supplier.

Before the new company was set up, the co-operatives were responsible for Atria’s meat procurement, producer guidance, services (e.g. animal trading and transport) and health care. A-Farmers improves the opportunities of the entire Atria meat chain in the increasingly global competitive environment.

2000

2000

The most modern logistics in Europe

An automated logistics centre, advanced even on a European scale, is completed at the Nurmo food factory.

1999

1999

“A world of flavours”

Atria acquires a company called Liha ja Säilyke and the Forssan brand. Around the mid-1990s, the company had brought its products under the Forssan brand and created a slogan for it: “Enter a world of flavours with Forssan!”

1998

1998

Atria’s sausage to the Guinness World Records book

Atria makes the world’s longest sausage. The 42-metre sausage is accepted to the Guinness World Records book. Next to the record-long sausage are master sausage maker Tapani Pietilä (left), product development manager Tuomo Sillanpää and product group manager Jorma Turunen.

1997

1997

Atria becomes a major player in Sweden

Atria makes a significant move in the Nordic meat market: it acquires Sweden’s largest private meat company Lithells, known for its sausages. The deal also includes one of Sweden’s most valued brands, Sibylla.

When Atria acquires Swedish Lithells in 1997, it becomes the largest meat company in the Nordic countries. The meat processor now employs more than 3,300 people and posts net sales of over 3.3 billion Finnish markkas. One third of its net sales comes from Sweden and export trade.

At the time of the acquisition, the Swedish meat industry is experiencing a similar turmoil that was seen in Finland half a decade earlier. Free trade brought by the EU and competition between increasingly global retail chains pose great challenges for producer-driven meat companies. The co-operative Scan Group has been Sweden’s biggest meat sector company. Lithells and Sardus have been the largest private companies.

Major reorganisations are set in motion in Sweden, with Finnish Atria and its CEO Seppo Paatelainen as one of the prime movers. According to Paatelainen, Atria’s leaders also looked into the acquisition of Sardus as part of a plan for Atria to grow substantially in the Baltic Sea region.

By acquiring the company founded by Oskar Lithell, Atria gains possession of one of Sweden’s most valued brands, Sibylla . Over the years, this sausage brand has grown into Sweden’s second largest fast-food chain after McDonald’s. The Sibylla concept is also rapidly expanding outside Sweden, and it already has outlets in nine European countries. Atria’s step into Sweden also means a leap into the global fast food market.

1996

1996

Pit-Product is created

The roots of the Russian Pit-Product brand go back to 1996, when the Pit-Product group of companies is founded in St Petersburg. Atria acquires Pit-Product in 2005.

1996

1996

Lighter ship sails at full speed

The company, now called Atria, prospers and grows, albeit after a tough period of reorganisation. Inexpensive imported meat, enabled by the EU, does not take over the shops after all: Finnish consumers favour Finnish meat.

When Finland joins the European Union in 1995, Finnish meat production and processing does not collapse – despite such fears. Although imports of foreign meat increase and retail prices of meat products fall considerably, Atria comes out a winner and becomes the country’s leading meat industry company. Its success is based on determined reorganisation and Finnish consumers’ preferences.

Atria – then Itikka-Lihapolar – eliminates overlapping functions and reduces costs by implementing an extensive reorganisation programme. As a consequence, only three out of eleven production plants remain in operation: Nurmo, Kuopio and Kauhajoki.

The first plant to be shut down is a pig slaughterhouse in Oulu right after the merger of Itikka and Lihapolar in 1991. A slaughterhouse and cutting department in Ylivieska are the last plants closed in 1996. Jobs are lost in the provinces.

“Without these moves, Atria would not be what it is today. We were also building something new at the same time,” says Juha Gröhn [linkki vuoteen 2011: Oman talon mies siirtyy johtoon], business development manager and later CEO of Atria, who led the taxing negotiations.

In addition to the reorganisation programme and the new factory in Nurmo, Atria’s success is contributed to by Finnish consumers.

“It seems it is more important to Finns to eat Finnish food than we anticipated,” Esko Aho, then prime minister, describes.

1994

1994

VK brand is created

Estonian Vastse-Kuuste is established in Põlvamaa, Southern Estonia. The company’s core operations include the production of meat, sausage and hams. Atria acquires Vastse-Kuuste and the VK brand in 2008.

1994

1994

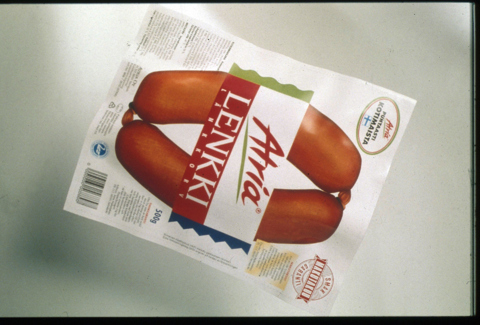

Wilhelm brand is launched

The Wilhelm product range is launched in 1994 under the name ‘Mestari Wilhelm’. The range includes barbecue sausages, frankfurters, meatballs and mustard. In 1999, the name is shortened to Wilhelm and the selection is narrowed down to class A barbecue sausages.

1994

1994

Name changed to Atria

The main brand Atria is adopted as the company’s name. The listed company Atria Group Plc becomes Atria Plc. The Atria brand was previously used jointly by co-operative slaughterhouses. The Atria logo and brand were created in 1991.

1993

1993

Wõro is founded

Estonian Wõro Kommerts AS is founded. Atria acquires the company and its brand Wõro in 2008.

1992

1992

Big ship close to sinking

The start of the new Itikka-Lihapolar’s journey is shadowed by large debts and fears about the EU.

When public limited company Itikka-Lihapolar starts operating, Finland is experiencing the deepest recession in its history. Unemployment is high and consumers have very little money to spend. The massive food factory completed in Nurmo in spring 1992 has cost Itikka almost 400 million Finnish markkas. The company’s total liabilities exceed one billion markkas. The new company also has many expensive, overlapping functions. It is in dire need of reorganisation.

At the same time, Finland decides to join the EU. People working in the meat sector estimate that in a deregulated market, the share of imported meat – particularly Danish meat – could rise to 30 per cent of Finland’s meat supply and prices could halve. Finnish meat would then drop to the second place.

“This was the only time when I thought it would be awful to look in the mirror and realise that I’m the director who steered this company into the rocks,” CEO Seppo Paatelainen said later, describing his feelings.

“The frightening thought that this great industrial plant could in the future stand as a memorial to Finnish agriculture is not foreign either,” says Reino Penttilä, chairman of Itikka-Lihapolar’s board of directors, in his speech at the opening of the Nurmo food factory in spring 1992.

In the early days of its operations, Itikka-Lihapolar is the big ship of the Finnish meat industry that is close to sinking, nearly touching ground. Only a few years later, the ship is much lighter and sailing at full speed.

1991

1991

Restrictions to competition removed

A wide gate to the future opens for Itikka-Lihapolar when the co-operatives close down their central organisation, which has restricted free competition.

For decades, the development and growth of the co-operative slaughterhouses had been obstructed by the division into regions and territories supervised by the central organisation owned by the co-operatives, Tuottajain Lihakeskuskunta (TLK). It defined the areas of operation, ‘home provinces’, within which the co-operatives had to stay. Competition was not free nationally. TLK also negotiated important export deals with the Soviet Union and handled nationwide marketing for the co-operatives.

In addition, TLK had its own industrial operations. It had acquired a meat company called Helsingin Kauppiaat (HK) in the 1970s. Northern Finnish co-operatives felt that TLK was mostly protecting the interests of Southern Finland. The conflict with Itikka in particular escalated when TLK began to build a large meat processing plant in Vantaa when at the same time Itikka’s food factory was being constructed in Nurmo. A clash with the central organisation was inevitable, and TLK’s dismantling was set in motion.

The core group pushing for TLK’s closure consists of the leaders of Itikka-Lihapolar, the company established by Itikka and Lihakunta the previous year: CEO Seppo Paatelainen, deputy CEO Paavo Jauhiainen and chairman Reino Penttilä. After a complex operation that attracts widespread publicity and has strong political overtones, TLK is dismantled. Towards the end of the operation, south-western Finnish LSO also begins to support the dissolution.

As a result, TLK is converted to HK Oy and sold to LSO. This is the beginning of the company that will be known as HK Ruokatalo. The most valuable asset obtained by Itikka-Lihapolar from TLK is the well-known Atria brand, to which the company is granted exclusive right.

The dismantling of the central organisation removes the greatest obstacle to free competition between meat companies and opens the gate wide for Itikka-Lihapolar to enter Southern Finnish shops, department stores and institutional kitchens.

1990

1990

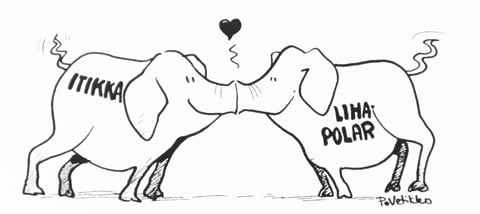

Finland’s leading meat company is established

Itikka and Lihakunta join forces and establish Itikka-Lihapolar, Finland’s leading meat company. The basis for Atria as it is today it is created.

Itikka’s and Lihakunta’s leaders estimated as early as the mid-1980s that joining forces would make sense for meat producers and co-operatives. Restrictions to trade were being removed and competition was opening up and intensifying both in Finland and the rest of Europe. In order to succeed in this new situation, Itikka and Lihakunta would need to increase the efficiency of their slaughterhouses and find new markets for meat products in Southern Finland, and potentially outside Finland.

The merger project is accelerated after the incorporation of the co-operatives’ slaughterhouses in 1988. The keenest advocates and implementers of the merger are the same men who promoted the founding of the limited companies: Itikka’s managing director Seppo Paatelainen and chairman Reino Penttilä and Lihakunta’s managing director Paavo Jauhiainen.

The merger takes place in autumn 1990. Itikka-Lihapolar Oy, Finland’s largest meat sector company, is created. It purchases more than 40 per cent of the meat produced by co-operative slaughterhouses, and its share of the meat products sold in the market is about one fifth. The company employs 2,200 people. Seppo Paatelainen is elected CEO and Paavo Jauhiainen deputy CEO.

The meat company is further reinforced when it acquires Pohjanmaan Liha Oy, which operates on the Ostrobothnian coast. Itikka-Lihapolar goes public in summer 1991.

The merger shakes the power structures in the meat industry and causes a great public debate, the tone of which is mostly positive.

“We can be proud that in this country where it is customary to resist change and say that time is not ripe yet we have leaders who are able to make decisions and act” describes the editorial of Pellervo, a co-operative magazine.

“It (the merger) was a shock to TLK and LSO, above all. They knew they were up against a major protester,” says CEO Seppo Paatelainen in an interview with Kauppalehti, a financial newspaper.

LSO, a co-operative of south-western meat producers, and its slaughterhouse company is Itikka-Lihapolar’s main competitor in Southern Finland. Tuottajain Lihakeskuskunta (TLK), the central organisation owned jointly by the co-operatives, also becomes a competitor to Itikka-Lihapolar and the other co-operatives: over the years, TLK has developed its own industrial operations and was planning to build a large meat processing plant in Vantaa – concurrently with the construction of Itikka-Lihapolar’s massive food factory in Nurmo.

Seppo Paatelainen, Reino Penttilä and Paavo Jauhiainen were the contributors to the co-operatives’ decision to dismantle TLK later in 1991.

1989

1989

CampoMos enters the Moscow market

The story of the Russian CampoMos brand begins when meat processing company OOO Campomos starts operating in Moscow. Atria acquires the company and the brand in 2008.

1988

1988

Preparing for the future: co-operatives turned into limited companies

In the face of international competition and major investments, the co-operatives’ resources are insufficient. In order to go forward, they need money from investors and an entirely new model of operation. Despite fierce objections, the Itikka and Lihakunta co-operatives convert their slaughterhouses into limited companies that are listed on the stock exchange.

In the late 1980s, Finnish agriculture, meat production and co-operatively owned slaughterhouses are going through the greatest transformation in their history. Competition is opening up in Europe and the so-called controlled economy, related to trade with the Soviet Union in particular, begins to crumble.

The problem in agriculture is substantial overproduction. In order for co-operative slaughterhouses to succeed internationally, they must be converted into larger, more productive and more efficient production plants. This requires a great deal of money.

Competition between slaughterhouses also changes in the domestic market. The co-operatives’ central organisation, Tuottajain Lihakeskuskunta (TLK), is put on a collision course with Northern Finnish co-operatives, in particular, when it develops its own, competing industrial operations. The conflict leads to the closing down of TLK.

The co-operative slaughterhouses in Seinäjoki (Itikka) and Kuopio (Lihakunta) begin to simultaneously prepare for transitioning to an era of deregulation and intensifying competition. The co-operatives’ leaders are thinking along the same lines: co-operative slaughterhouses must be incorporated into limited companies. This will secure sufficient financing and enable more flexible development of the operations.

At Lihakunta, the idea is advocated by managing director Paavo Jauhiainen, and Itikka’s architects of change are newly-elected managing director Seppo Paatelainen and chairman Reino Penttilä, the supreme decision-maker of both the co-operative and the co-operative slaughterhouse. The incorporation projects are strongly objected by leading co-operative players, and public debate is fierce.

Paatelainen and Penttilä’s proposal for incorporation is unanimously approved by all of Itikka’s decision-making bodies. The co-operative’s slaughterhouses and commercial operations are transferred to the new company, Itikka Lihabotnia Oy. The co-operative continues to be responsible for animal procurement and trading.

The company is listed on the Helsinki Stock Exchange in the same year. It is the first listed company converted from a co-operative to a limited company, the first meat company to go public and the first listed company in the province. Nevertheless, Itikka Co-operative continues to have the highest decision-making power in the company.

Lihakunta’s incorporation takes place slightly later but in the same manner. A company called Lihapolar Oy is founded to be in charge of production and sales and listed on the stock exchange. The co-operative is the majority shareholder in this company as well.

The incorporation of Itikka’s and Lihakunta’s co-operative slaughterhouses sets in motion the reorganisation of the entire meat sector. As a result, Finland’s leading meat company is created and slaughterhouses owned by meat producers also begin to compete in the market.

1987

1987

Ridderheims is created

Ridderheims is created in entrepreneur Christer Ridderheim’s kitchen. A passion for food drives him and his friend Peter Grönvall to make pickled cucumber for Gothenburg’s shops. Atria acquires the Ridderheims brand in 2008.

1987

1987

New captain, new direction

Itikka Co-operative’s new managing director Seppo Paatelainen is a forward-looking change manager. Under his leadership, the co-operative slaughterhouse operations are incorporated, the company goes public and Itikka and Lihakunta are merged into Finland’s biggest meat industry player. Additionally, the company’s name is changed to Atria, it is trimmed in preparation for entry into the EU and it begins its expansion to the Scandinavian, Baltic and Russian markets.

1982

1982

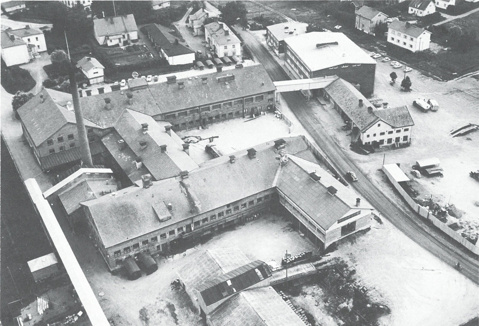

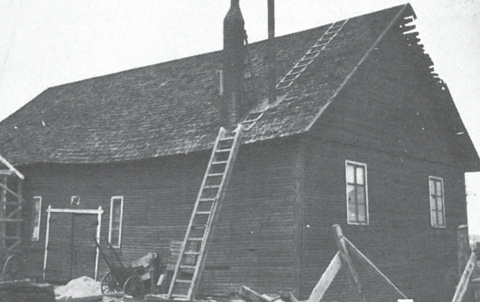

Modern pork line completed in Nurmo

The building of Itikka’s pork line in Nurmo takes one and a half years. The result is a cutting-edge production unit with an annual throughput of 300,000 pigs.

At the end of January 1982, a commissioning inspection is carried out in Nurmo on the pig line unit of more than 100,000 cubic metres.

The equipment is first tested by taking in a small number of slaughter animals. Everything goes well and the facility is up and running in no time. Slaughtering goes according to plan, the quality of carcasses is better than before and the new chilling technology reduces meat weight loss.

Large-scale cutting operations right next to the slaughterhouse prove to be a wise choice, and the cutting department’s daily quota of 1,000 pigs is reached faster than expected.

The investment makes it possible to work efficiently and reduce wastage. The millionth pig passes through the line in March 1985 and the two millionth in 1988.

1979

1979

Lihakunta’s transformation begins

Under the leadership of its new managing director Paavo Jauhiainen, Lihakunta implements a ten-year change and investment programme, during which old capacity is demolished and new capacity is built. The programme is expensive but effective.

A major, ten-year investment programme is approved in 1979 under the leadership of Jauhiainen. The programme includes setting up new slaughterhouses and eliminating old production capacity.

The strategy means severe rationalisation measures for the industry, the first of which is the closing down of the slaughterhouse in Varkaus. This is followed by a period of heavy investment and dismantling of outdated capacity. Statutory employer-employee negotiations are under way almost constantly in some part of Lihakunta’s organisation.

In 1981, production volume with just over 1,700 workers is 80 million kilograms. Ten years later, 106 million kilograms is produced with 1,400 people. The company’s equity ratio increases from about 20 per cent to 45 per cent, and its net assets multiply.

In 1981, Lihakunta acquires part of Osuustukkukauppa’s (OTK) meat industry. Lihakunta obtains the slaughterhouses in Ylivieska and Iisalmi and the meat product plants in Oulu and Kuopio. After the period of rationalisation, Lihakunta has production facilities in ten locations.

1977

1977

The great move from Seinäjoki to Nurmo begins

A freezing plant is built in Nurmo, after which Itikka’s production is gradually moved from Seinäjoki to Nurmo.

1975

1975

Difficulties with reindeer meat

Lihakunta acquires Pohjolan Liha Oy, which operates in Rovaniemi and produces reindeer meat, among other products. Later, it is noticed that making a profit on reindeer meat is difficult.

The merger with Karjapohjola and the acquisition of Pohjolan Liha in 1975 turn Lihakunta into a major meat industry player geographically, but the results in the northernmost dimension are not impressive, at least not for reindeer products.

Nevertheless, reindeer farmed in Lapland is included in Lihakunta’s selection until the late 1980s. That is when Lihakunta establishes Poropolar Oy together with reindeer herding co-operatives.

Paavo Jauhiainen, Lihakunta’s colourful managing director, says later that Poropolar was never able to make money out of reindeer products. The processing of reindeer meat is one of the few mistakes made by Lihakunta over the course of its long history.

1975

1975

Itikka acquires Maan Liha

The ownership of Kauhajoki-based Maan Liha is transferred to Itikka following a share transaction. Maan Liha has the most modern and efficient cattle slaughterhouse in the Nordic countries.

At the time of the share transaction, in 1975, Maan Liha’s modern production facility in Kauhajoki measures 10,000 square metres. After Itikka’s fire, all slaughter operations are transferred to Kauhajoki. Even overloaded, the plant manages to perform all of its tasks. Itikka gains valuable experience of separating cattle and pig slaughter, and makes a far-reaching decision about two separate slaughterhouses.

All beef processing is left for Maan Liha. Pork processing is first concentrated to Seinäjoki and later to Nurmo. Meat procurement in Itikka’s area of operation continues through two networks, Itikka and Maan Liha. The system is disputed, but it achieves approval when purchase prices and the purchasing policy are harmonised.

1975

1975

Burnt-down broiler slaughterhouse is replaced with a new one

The production volumes of the broiler slaughterhouse are increased in 1974, but the following year, the entire line must be rebuilt after a fire. A separate section for chicken slaughter is built at the same time.

1974

1974

Lönneberga is created

The recipe for the Lönneberga ham has its roots in the 1930s, when butcher Hugo Hedman from Jämtland, Sweden, creates it. The name Lönneberga is introduced in 1974 by Hugo’s son Lars Hedman. The brand is transferred to Atria as part of the acquisition of Sardus.

1972

1972

Lihakunta’s area of operation expands

Lihakunta expands to cover more than half of Finland when Northern Finnish Karjapohjola is merged into it. Lihakunta’s market is large, but the distances are long.

Finnish co-operative slaughterhouses are in fairly bad shape financially, which leads to the founding of larger, more efficient and more profitable slaughterhouses. The mergers of slaughterhouses start in the late 1960s. The most significant arrangement in the early 1970s is the merger between Lihakunta and Karjapohjola in 1972.

After the merger, Lihakunta’s area of operation covers about 60 per cent of the country. Consequently, Lihakunta gains control of the so-called northern dimension. The co-operative has almost 50,000 members, and more than a million Finns live in this large area.

The merger increases Lihakunta’s market area and production capacity, since Karjapohjola has slaughterhouses in Oulu, Rovaniemi and Ylivieska, as well as meat product and processed food plants in Oulu. Lihakunta purchases approximately 24 million kilograms of meat every year.

In 1975, Lihakunta acquires Rovaniemi-based Pohjolan Liha Oy from the K-Group, after which its area of operation extends from Savonia to Lapland.

1970

1970

Chicken production begins in Seinäjoki

Growing demand creates a need for Itikka’s chicken production. After a cautious start, broiler houses are rapidly scaled up to the planned size.

Chicken consumption begins to show signs of growth also in Finland in the early 1970s. Since chicken farming has already been started elsewhere, Itikka’s management decides that chicken production must be immediately set up in South Ostrobothnia.

The poultry slaughterhouse is remodelled and a new hatchery is built in Itikanmäki in 1970. Initially, broiler houses of 30,000 birds are planned, but it is then decided that units of 15,000 birds will be built that can later be increased if necessary.

Production is organised into two phases in separate laying houses and broiler houses. The next task is to find producers who are willing to invest in new production buildings and take the risk of engaging in an as-yet-unknown field of production.

Profitability estimates turn out to be accurate, and broiler houses that are half the size initially planned can soon be doubled. The operations grow rapidly, and the limit of two million kilograms is exceeded in 1977.

1970

1970

Pastejköket is created

Pastejköket is a product of Sjöquists Livsmedel AB, a traditional Swedish manufacturer of processed meat products. In 1970, the company begins to make liver and meat pâté under the name Pastejköket. The brand is transferred to Atria as part of the acquisition of Sardus AB in 2007.

1969

1969

Itikka builds a sausage packing and pricing line

The first packing and pricing unit operating as a production line is built as an extension to the sausage line.

Self-service shops become more common, creating a need for suitable products and services. Packing sausage into thin plastic bags is the first attempt to create such a product.

Sufficient packing capacity is achieved in Itikanmäki when the first packing and pricing unit operating as a production line is built as an extension to the sausage factory in 1969.

Packing increases rapidly when vacuum packs are introduced only a couple of years later as machines and materials advance. The shelf-life of sausage extends to three weeks. At the same time, the packing of sausage and expensive special products in slices begins. Dates are added to packaging, and shops start to price products with the introduction of special offers.

By the early 1970s, Finnish consumers and shops realise that packaging is an integral part of high-quality products and services.

1963

1963

Atria brand is introduced

TV commercials contribute to the creation of the Atria brand. The brand is seen in Tuottajain Lihakeskuskunta’s advertisements.

TV programmes and commercials paid for by advertisers rapidly gain in popularity in Finland in the 1960s. They enable the inception of proper television service. When the broadcasting time is short, Finns also want to watch advertisements. New brands are needed for the new medium.

The brands of provincial co-operative slaughterhouses cannot be advertised on TV, which is why a joint brand must be created for the new marketing medium. The Atria brand is established in 1963 as the joint brand of Tuottajain Lihakeskuskunta (TLK), the central organisation of the co-operative slaughterhouses.

Atria is granted exclusive right to the brand in 1991, when TLK is dismantled. The valued brand becomes the name of the entire Group in 1994.

1962

1962

Canned food factory is completed, but sales are low

The initial sales of canned foods prepared by Itikka are modest, since Finns want to buy fresh meat and sausage from shop counters.

The last major investment of the post-war decade is the construction of Itikka’s canned food factory.

Canned food is expected to become as popular as in Sweden and America. The new equipment has a high production capacity that enables mass production. The plan is for the factory to produce not only canned meat and processed food but also products made from Finnish berries.

However, the sales of canned food do not grow as projected, since Finns’ consumption habits do not change in the expected direction. The shop network equipped with refrigeration devices guarantees the supply of fresh meat, sausage and processed food for consumers.

In the years that follow, the premises of the canned food factory built in 1962 are gradually taken over by the production of sausage and processed food. It will be a while before canned food will conquer Finland.

1960

1960

Modernisation of the Itikanmäki production plant is completed

With the re-expansion of the lairage, the modernisation of the entire production plant is completed in 1960. Itikka now has sufficient reception and throughput capacity to meet the increased demand for products.

1956

1956

Name changed to Lihakunta

The name of Lihakunta’s predecessor, Savo-Karjalan Osuusteurastamo, is felt to be unsuitable for a company that is increasingly engaging in industry and trade. The snappy ‘Lihakunta’ is chosen as the co-operative’s new name.

When the new slaughterhouse in Likolahti, Kuopio, is finished, the construction of a meat product plant begins immediately. The “sausage factory” is completed in 1954.

When the new production plant is up and running, Savo-Karjalan Osuusteurastamo (SKO) comes to the conclusion that its name is outdated. It is considered that the name does not provide an accurate picture of the industrial enterprise. A new, short and snappy name is needed.

The name ‘Lihakunta’ is registered in September 1956. At the same time, the organisation is updated by adding a commercial department to the company’s management.

1955

1955

Itikka expands to meet growing demand for sausage and processed food

The range of foods bought by Finns broadens, leading to the expansion of the factory in Itikanmäki.

Itikka’s factory in Seinäjoki can no longer fully satisfy the demand for sausage, which has grown in the 1950s. More space is needed.

A new meat product plant is built on top of and next to the old factory. The plant is opened at the end of 1955, after the conversion of the premises on the ground floor for the use of the shipping room and the processed food factory.

The following year, sufficient space is allocated to expand the range of processed and convenience foods. Despite this, most of the production remains manual. Over the next ten years, the manufacturing volume triples.

1953

1953

Lairage is expanded and a poultry slaughterhouse is added to it

Industrial operations in Itikanmäki grow rapidly: the lairage is expanded and poultry slaughter is started.

When Itikka’s lairage is expanded in the 1950s, most of the slaughter animals are young calves, grass-fed calves and bull calves. Their meat rarely weighs more than one hundred kilograms. However, the conditions for meat production improve and Itikka’s growing share of procurement raises slaughter volumes every year. The rising standard of living increases the consumption of meat products.

Itikka begins to slaughter chicken as early as the late 1940s. Chickens are collected for slaughter, which takes place at a corner of the pig slaughterhouse. There the birds are scalded in a tank of hot water and plucked on top of a rotating drum with rubber fingers.

Everything is done by hand until new machines enable production line slaughter at Itikka’s poultry slaughterhouse in 1953. The slaughter line built in the attic of the lairage has sufficient capacity to meet the needs of that time.

1952

1952

Slaughterhouse industry is born in Likolahti

A new slaughterhouse is completed in Likolahti, Kuopio, giving rise to the concept of ‘slaughterhouse industry’.

Savo-Karjalan Osuusteurastamo’s (SKO) membership and animal procurement volumes grow significantly in the early 1950s. Old livestock shelters and warehouses have become major bottlenecks. It has even been necessary to slow the reception of cattle, since the processing facilities are too small. A new slaughterhouse is needed.

The new, large slaughterhouse is built in place of the old cattle and pig slaughterhouse and lairage in 1952. The building has three floors. The workflow has been redesigned: all shelters from lairage to the shipping room are now under the same roof. Where possible, manpower has been replaced by industrial processes.

The construction of a meat product plant begins immediately after the completion of the slaughterhouse. The plant is completed in 1954. A destruction plant has been completed only a year earlier. The co-operative’s decision to build a new slaughterhouse almost entirely with debt was a bold one, since expansion projects in Joensuu, Varkaus and Nurmes were also under way around the same time.

1950

1950

3-Stjernet is founded

Aage Jensen establishes 3-Stjernet in 1950. He is a butcher interested in manufacturing salami. Jensen tries out salami making in his own small facility and then travels around in freight trains selling the sausages he has made. In 1967, Jensen sets up the 3-Stjernet factory in Horsens, Denmark.

1950

1950

Another topping off ceremony in Itikanmäki

Topping off ceremonies are an annual event in Itikanmäki. Expansions are set in motion when the demand for sausage grows at an accelerating pace.

As sausage sales increase, the premises in Itikanmäki become too small and plans begin to be drafted for new expansions in the late 1940s. More land is acquired on the other side of Vaasantie road. Topping off ceremonies become an annual event in Itikanmäki.

The following are put into operation in 1950: the extension to the meat storerooms, cooling rooms, the first deep-freeze storerooms and modern office premises.

The plan for a new factory is approved at the beginning of 1954. Additional premises are built next to and on top of the old premises and completed in 1955. Brand new premises are allocated to the sausage factory upstairs, with separate rooms for cutting, manufacturing and cooking. Modern, large, efficient machines are purchased for each department.

The extension on the ground floor includes product storerooms and a shipping room, in which work is carried out in stages. The former sausage-making facilities are taken over by the processed food factory. When completed, the sausage factory even has 200 extra square metres, so there is room to grow.

The factory is preparing for a phase in which the Finnish population is taught to eat plenty of sausage for financial reasons. The retail price of sausage is reduced by 20 per cent. As compensation for this loss, producers receive government subsidies. The consumption of sausage grows by 20 per cent, so the extra space in the factory is soon filled with activity.

1938

1938

Area of operation expanded, name changed to Savo-Karjalan Osuusteurastamo

Kuopion Karjanmyyntiosuuskunta’s area of operation expands to North Karelia and the co-operative’s name is changed to Savo-Karjalan Osuusteurastamo (SKO).

Kuopion Karjanmyyntiosuuskunta’s (KKO) operations expand geographically when Karjakauppaosuuskunta Oiva, which has operated in Joensuu, North Karelia, falls into its hands.

Following the expansion, KKO establishes an office in Joensuu. A slaughterhouse and a meat processing plant are also built there right before the breakout of the Winter War with the Soviet Union. An office is also opened in Sortavala, Karelia, which was later ceded to the Soviet Union.

In 1938, the co-operative’s name is changed to Savo-Karjalan Osuusteurastamo. Just before the Winter War, the sales of processed meat exceed one million kilograms. Meat procurement surpasses three million kilograms.

During the Second World War, battles are fought in part of SKO’s business area. Meat production falls dramatically due to emergency slaughter, and meat products are rationed. SKO must perform an unpleasant task: meat requisitions.

During the war, both management and workers are pushed to their limits.

Nevertheless, they have strong faith in the future, and they already have their eyes set on Likolahti in Kuopio. The war, however, freezes all plans for several years.

1937

1937

Sausage factory completed in Itikanmäki

A new sausage factory is completed in Seinäjoki. The old factory starts to produce the predecessors of modern convenience foods, such as black pudding and liver casserole.

When the new premises of the sausage factory are completed in early 1937, it is stated with pride that they meet the strictest requirements. The factory has tiled walls and is mostly fitted with new machines, so the move from the old workshop means a huge step forward.

At one end of the working room is a cutting table where the meat is brought from behind the wall, from the meat storeroom. Boneless meat is salted and stored in the adjacent cooling room. At the northern wall of the room is an electric motor that generates power for a mincer, a cutter and other machines. Sausage is stuffed using water pressure and tied manually. There are separate cooking and smoking rooms.

Up until now, Itikka’s sausage has been prepared for 20 years in a small wooden building, where the production volume per day was only about 600 kilograms in the last year of operation.

The old factory has mainly served the village residents, and it continues to be used for production when the premises are converted into a shop kitchen. The term ‘convenience food’ does not yet exist, but ready-made foods are prepared at the old sausage factory. This is the first shop kitchen in Atria’s history, and it marks the beginning of Atria’s convenience food industry.

1932

1932

The first Sibylla hot dogs are made

Oskar Lithell and his family business, which grew rapidly in the early 1900s, are also behind the Sibylla brand. The first Sibylla hot dogs are made at Lithells’ sausage factory in 1932. They have such a royal flavour that a royal name is also needed for the new product: the name Sibylla comes from the then princess of Sweden. Atria obtains the Sibylla brand as part of the acquisition of Lithells.

1928

1928

KKO purchases its first cattle transporter

Motorisation and improved transport links in the 1920s gradually put an end to the purchasing of on-farm slaughtered meat. The completion of Kuopion Karjanmyyntiosuuskunta’s (KKO) own slaughterhouse increases the interest in purchasing live animals.

When KKO acquires a tailor-made lorry in 1928, slaughter animals can be transported over increasingly long distances. At first, animals are collected from agreed collection points where producers have taken them. ll the same, it is quite a hassle to get the animals into the lorry.

1927

1927

Arbogapastej brand is created

Carl A. Carlson’s meat cutting company is established in Arboga, Sweden. Carl and his brother Knut Carlson begin to make and sell sausage, brawn and pâté in their shop at the market of Arboga. The brand is transferred to Atria as part of the acquisition of Sardus AB in 2007.

1917

1917

Itikka builds the first sausage factory in Seinäjoki

Plans for the further processing of meat are set in motion immediately when livestock sales co-operative Itikka moves to Seinäjoki.

Home slaughter involves the making of brawn, and the plan is to also include it in Itikka’s operations. Autumn slaughter days at local farms are filled with cooking, as brawn is jiggled for half a day, brought to a boil in a pan and baked in an oven.

In September 1915, Itikka’s Board of Directors decides to turn a sauna into a sausage-making facility and hire master sausage maker W. Sillgren from Seinäjoki as its employee.

Sausage-making in a purpose-built factory does not begin until 1917. Machines must be bought second-hand, since the country is at war and foreign trade has stopped. Approximately 28,000 kilograms of sausages and brawn is manufactured in 1920.

Paul Koch is employed as master sausage maker, and he brings with him the old German sausage-making tradition. Manufacturing volumes grow every year, which shows that Ostrobothnians have welcomed industrial sausage-making.

1914

1914

Atria’s second roots in western Finland

Itikka Co-operative, one of the most important co-operatives in Finland, is born in 1914, when a livestock sales co-operative is founded in South Ostrobothnia.

Etelä-Pohjanmaan Karjanmyyntiosuuskunta Itikka (South Ostrobothnian Livestock Sales Co-operative Itikka) is established in Seinäjoki in 1914. The meeting is attended by conscious farmers and co-operative activists. Actual operations only begin a little later, when the co-operative has enough members.

University graduate Yrjö Collan, who has been involved right from the beginning, is asked to become the co-operative’s first managing director. Operations start with the joint export of slaughter cattle to Sweden, which is why the first place of business is located in Vaasa. During its first year of operation, Itikka trades and slaughters more than 2,000 animals.

The first transactions lead to disappointments, but they also teach valuable lessons for the future. Serving South Ostrobothnian farmers is prudently set as the objective of the operations. The following year, net sales double. In its third year of operation, the co-operative finally gets a permanent director, when Oskari Herttua takes up the post.

Finland’s participation in World War I under Russian rule causes major difficulties for livestock sales. At first, the agency that procures food for the military takes meat by force. Later, requisitions stop when farmers guarantee the voluntary supply of sufficient quantities of meat.

It takes until 1917 that the co-operative is able to properly begin the development of its operations and the further processing of meat.

1910

1910

Maks & Moorits is created

The roots of the Maks & Moorits brand extend to the Estonian company AS Valga Lihatööstus, founded in 1910. The company and the brand are acquired by Atria in 2005 .

1910

1910

Everything done by hand at the first “sausage factory”

Kuopion Karjanmyyntiosuuskunta (Kuopio Livestock Sales Co-operative, KKO) takes its first steps as a meat processor and buys a sausage factory in the centre of Kuopio. The work is done by hand.